Technological advancements have unlocked new possibilities and potential for innovation in the construction industry. Worksite optimization is now achievable with the intersection of advanced automation and integrated technologies. Our industry is rapidly evolving; with smart construction services & solutions, we keep up with the pace of change.

Trimble Full-Service Dealer

The Trimble Earthworks Grade Control Platform offers groundbreaking features. It is designed to help you do more in less time. State-of-the-art software and hardware give operators of all skill levels the ability to work faster and more productively than ever before.

Leica Full-Service Dealer

Gain the ultimate transparency into your construction activity and monitor progress in real-time from anywhere on any device. Easily visualize and share data through a powerful cloud solution and web interface.

GPS Solutions

GPS Hardware Services

- Base & Rover Systems (Rental, Sale & Repair)

- Aftermarket installations for Dozers, Excavators & Motor graders, and skid steers

- UHF and 915 conversion hardware

- Trimble Systems

- Leica Systems

- Topcon Aftermarket Systems

- Certified Warranty Technicians

Job Site Set Up Services

- Establishing OPUS/Control Points for Machine Control

- Localize the job site

- GPS Hardware setup

- 3D Modeling

- System Installs

Training and Consultation

- Base, Rover, Data Collector orientation, and localization training

- Operating Techniques for Grade Control

- Component identification and functionality

- Basic troubleshooting for signal loss and re-initialization

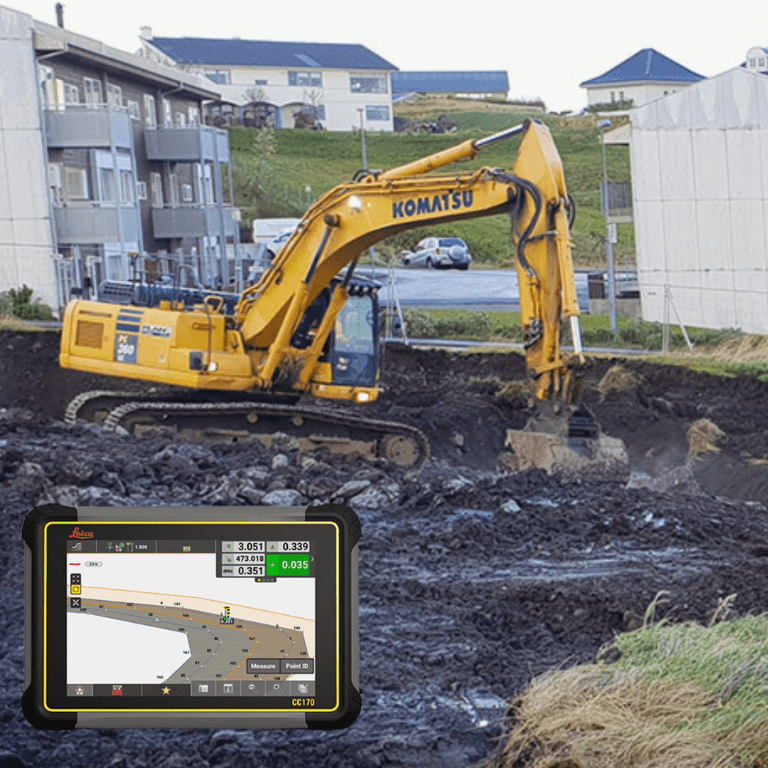

Intelligent Machine Control

Great technology solutions for you!

Condition Monitoring

This construction machinery service program allows you to detect problems before breakdowns occur. For construction fleets, our experts recommend using an oil analysis program to identify the current health of your products and extend drain intervals where possible. This will keep your fleet running smoothly and minimize unnecessary downtime.

Easily apply advanced automation technology to your job sites.

In today’s construction industry, technology has revolutionized the way we begin a job – we are way past beginning a job by pounding a wooden stake into the ground. With Komatsu’s Intelligent Machine Control (IMC), you can program 3D design data directly into your machines for enhanced efficiency. IMC utilizes sophisticated automation, allowing even operators with less experience to work smartly and effectively.

On your job site, productivity is the key to success, and with Komatsu’s IMC, you have a powerful tool to help you achieve maximum productivity faster. IMC incorporates advanced proprietary technology and cutting-edge job site design for sophisticated productivity-enhancing automation.

IMC Dozers

Through automatic dozing and rough cut-to-finish grade, IMC-equipped machines help you make every pass count to achieve superior production compared to traditional aftermarket systems.

- Innovative: Automated operation from rough dozing to finish grade

- Intelligent: New dozing mode and load control performance features

- Designed for the machine: Factory-installed, integrated system

- No cables: No coiled cables between the machine and the blade

- No climbing: GNSS antenna and mast removed from the blade

- No connections: No daily connections are required between the machine and the blade

- Fully supported: Get assistance via Komatsu’s service and support network

IMC Excavators

Give your operators the power to work more efficiently than they ever could with conventional aftermarket machine guidance (indicate only) or manual operation. Intelligent Machine Control excavators with semi-automatic control can work smart from rough digging to finish grading and help minimize over-excavation to make every pass count.

- Semi-automatic for trenching, slope work, and high-production applications

- Protection + precision + performance = the formula for pursuing maximum productivity versus conventional machine guidance