Waukesha Gas Engines – Powering your reliable, responsible energy future.

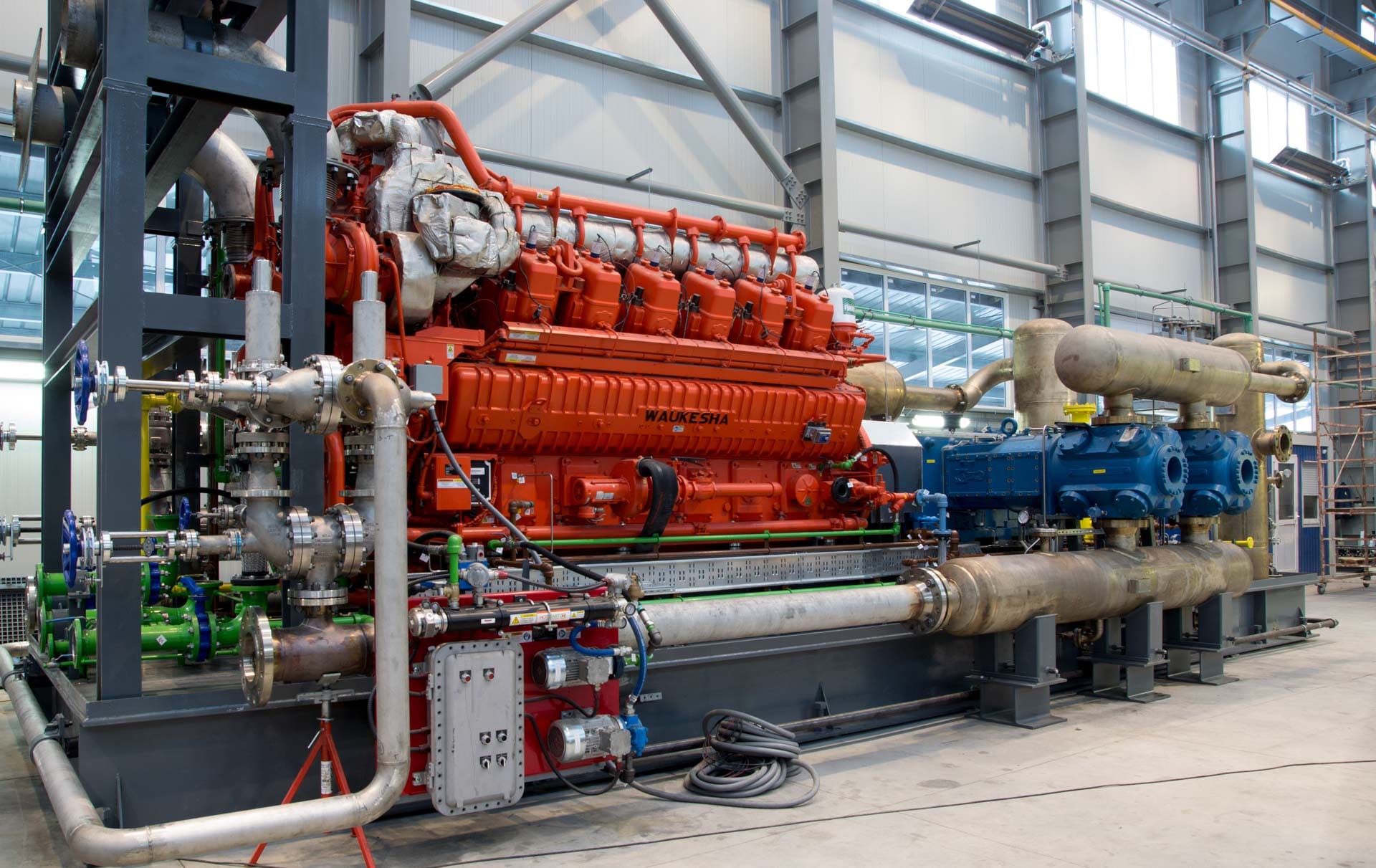

With nearly a century of experience, WPI is a trusted representative of Waukesha engine product lines. These engines are designed to operate in even the most challenging environments, including gas compression, power generation, and mechanical drive applications. Waukesha is committed to advancing engine technologies, introducing innovative services, and optimizing engine performance while minimizing environmental impact.

WPI is the right partner to lean on when economy and availability call for remanufactured engines. Our state-of-the-art facility is designed to reduce the environmental impact of the remanufacturing process and deliver an engine that will meet or exceed the manufacturer’s specifications.

From engine disassembly to final testing and painting, we’ve completely reengineered the remanufacturing process to make the engine faster, better, and more reliable. At the same time, we do everything possible to reduce the environmental impact of the process.

The process is documented at every step, and final testing is done in one of our two DS4010 Dynamometers equipped with an instrumentation package to record and view the engine performance.

Experience and expertise unmatched in gas compression

WPI has teamed up with Ariel for over thirty years to provide a complete range of gas compression equipment and services to the Upstream, Midstream, and Downstream Compression sectors. We are in the most significant shale plays in the US and Canada. Our Factory Certified training programs, conducted in-house, support our offerings and ensure that our service technicians are proficient in the latest industry requirements and technological advancements.

With decades of experience and state-of-the-art facilities, WPI offers Compression Revamping Services across many compressor package types. You spend millions acquiring, installing, and maintaining your compression fleet. Over the years, as your application conditions change, those compression assets may no longer be ideally configured for your needs.

Although your existing configurations may now be sub-optimized, the value-adding components of those packages can still have years of money-making life left in them. WPI’s team of revamp experts can help you reconfigure and repurpose underutilized compression assets, allowing them to continue generating production and profits for years to come.

When you partner with WPI, you will receive dependable service and efficient equipment. Additionally, you have access to a group of committed and skilled professionals who are ready to assist you with any problems and guarantee that you get the most out of your equipment investment.

Waukesha Pearce Industries (WPI) has been a leading provider of power generation and aftermarket parts for over half a century. We offer reliable aftermarket solutions for emergencies, standby, mobile, or prime power.

Our goal is to help our customers optimize the value of their engines by providing them with the necessary skills and knowledge. Our modular courses and training programs are designed to assist novice and experienced technicians develop and maintain their skills, keeping up with the latest technological advancements. Our team of experts is available 24/7 to handle any power generation parts and service requests. You can trust WPI to be your go-to source for all your power generation service needs.

Repair Service

Our team of certified technicians uses cutting-edge technologies to deliver safe, reliable, and professional solutions. WPI is agnostic to the type of engine. We specialize in Waukesha, Generac, and Caterpillar engines and power generators.

Our Power Generation Service Group currently consists of almost 100 dedicated personnel. Typical services include the following:

- Factory Trained Technicians

- Continuous Education for Technicians

- Over 30 service technicians covering the great state of Texas

- Load Bank Testing

- In-depth Knowledge of NFPA 110, Joint Commission Standards, and EPA

- Knowledgeable in local City, County, and State Requirements

- Service All Makes and Models

- One Number to Call for All Locations

- On Staff Technical Support Experts

- Waukesha Pearce is 24/7/365

- Hurricane Response

Repair Parts

At WPI, you can find the trusted brands and service parts you are looking for. Our skilled parts counter personnel can assist you throughout the United States with our maintenance solutions. To ensure your work is not disrupted, we keep a vast collection of OEM power generation parts and reliable repair products in stock at our accessible branch locations and distributed warehousing facilities.

Planned Maintenance

For optimal performance and reliability, WPI Planned Maintenance is the solution.

WPI has been a trusted name in power generation and support solutions since 1955. Our team has extensive expertise and experience in maintaining equipment at peak performance. Our service technicians are factory trained and continuously educated to stay updated with the latest industry procedures and requirements.

WPI is geared for maximizing uptime.

WPI has your gas compression needs covered with locations across significant shale plays in US and Canada.

Our experience and expertise are unmatched in the gas compression segment. WPI delivers a broad range of gas compression solutions for multiple applications. Our offerings are backed by continuous in-house and factory-based training programs, ensuring service technicians are up-to-date and qualified in the latest industry requirements and technological advances.

- Revamps of gas compressor packages

- Application engineering

- Emissions equipment and testing

- Repowering engines at a state-of-the-art facility

- Exchange engines

- 24/7 availability of aftermarket parts and services

- Dedicated field service technicians

- Fully-equipped field service trucks

- Distributor of Waukesha gas engines

- Distributor of Ariel compressor parts

Equipment

Output suffers if the equipment doesn’t work well and consistently. Our gas compression maximizes productivity and uptime by partnering with some of the most prominent names in gas compression to offer solutions for the most demanding applications.

Ariel World Standard Compressors

BHP Range 85-800HP

Ariel JGM/N/P/Q and JG/A/R/J

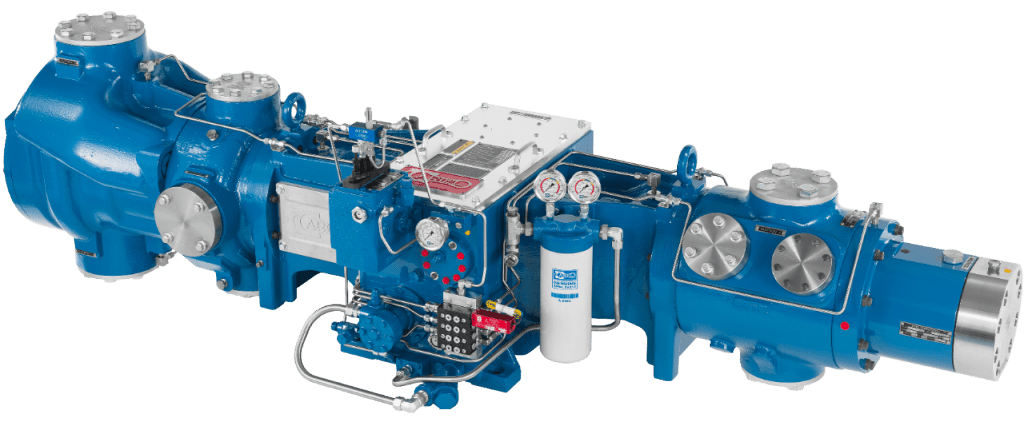

For decades, Ariel’s small horsepower units have been the trusted workhorse for gas lift, enhanced oil recovery, and small-scale gas gathering. With thousands of working units in the field, spanning various operating conditions, these small, separable reciprocating compressors are engineered to pair with high-speed diesel and natural gas engines effortlessly. These smaller units may also be paired with electric motor drives and high-pressure cylinders and are an excellent choice for compressed and renewable natural gas applications (CNG & RNG).

BHP Range 800-1800HP

Ariel KBK/T/E

These medium horsepower offerings are ideal for broad applications through the natural gas and processing value chain. Ranging from gas gathering to small plant processing, recycle service to larger high-pressure gas lift operations, these compressors are designed and built to last in continuous operation in the field. Where required in process and refinery operations, Ariel’s medium horsepower units have demonstrated the reliable ability to operate continuously for years without interrupting service.

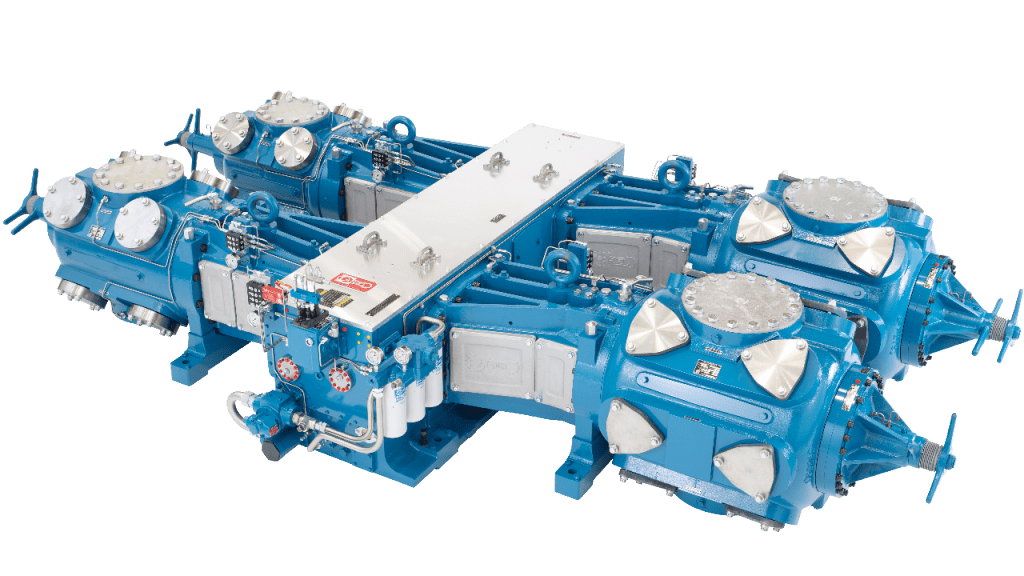

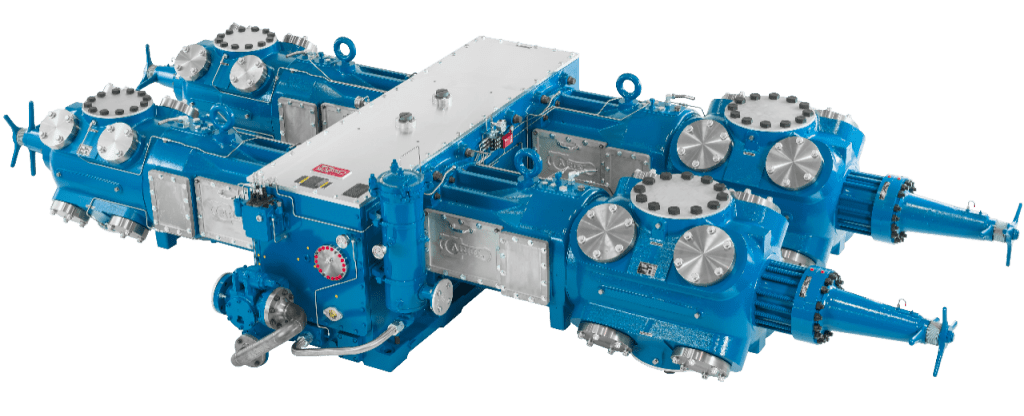

BHP Range 1800-10,000HP

Ariel JGC/D/F, KBC/D/F, KBU/Z, KBB/V

Ariel’s extensive line of large horsepower, medium-speed reciprocating compressors are designed to pair with electric motor or natural gas drivers for your most demanding applications. 1800-2500HP C/D units have become the standard bearer for modern, large-scale natural gas gathering operations supported by pad drilling throughout the world’s most prolific shale plays. Pipelines, headers, storage/withdrawal, and large cryogenic processing applications have become the common landing place for Ariel’s largest equipment. Whether boosting pressures along large diameter long haul pipelines or pushing high-pressure acid gas into sequestration reservoirs, Ariel’s are the most trusted large reciprocating compressor worldwide.

Dresser-Rand/Worthington

Worthington — The First Was Built to Last. Worthington introduced its first angle-type engine compressor in 1927 and continued until 1975. Many of these legendary compressors continue to serve faithfully every day.

Cooper delivers a full line of OEM-quality parts, service, repairs, and technical support to customers who want to keep their Worthington integral gas engine compressors running in peak condition. We provide OEM quality and modernized power cylinders, liners, pistons, heads, and more.

Parts & Accessories

The equipment you need is made even better with the peace of mind from leading gas compression service and parts solutions. WPI technicians’ extensive gas compression experience and product knowledge for all makes and models of natural Gas engines, combined with a vast array of parts and accessories, ensure we deliver world-class gas compression solutions to our clients.

Services and Trained Technicians

Every WPI gas compression service professional is trained in the latest products and procedures through continuous in-house and factory education and excels in field and shop repairs. Our technicians are standing by, ready to support your gas compression requirements 24 hours a day and seven days a week.