Supply and demand must be balanced to stay within extremely tight tolerances for frequency and voltage, or generating units trip off and cause a catastrophic blackout. ERCOT managed to avoid a total blackout, but property damage and business losses totaled tens of billions of dollars, and the human cost of the storm was horrific.

The volatility of the weather and the intermittency of renewable energies have brought real challenges to energy systems. Grid failure and crashing incidents are likely to continue and occur more often. Romany Webb, a researcher at Columbia University’s Sabin Center for Climate Change, said, “The reality is the electricity system is old, and a lot of the infrastructure was built before we started thinking about climate change. It’s not designed to withstand the impacts of climate change.

Demand-Side Flexibility

Demand-side flexibility is a practical solution to the US power grid’s supply and demand problem. Energy.Gov defines Demand Response (DR) as an opportunity for commercial and industrial managers in Texas to play a significant role in the electric grid operation by being flexible in reducing or shifting their electricity usage during peak periods.

Financial incentives to lower electric bills have typically driven ERCOT Demand Response Programs’ participation. However, sustainability in the form of carbon credits and corporate compliance commitments are becoming prominent reasons to participate.

Practical Power Resilience ™

Power Resilience has had a deeper meaning since that fateful day. Power resilience refers to having the ability to continue your operations without impact from disruption to your power supply. As we electrify more of what we do, we put ourselves at greater risk from power disruption, which can have significant financial implications.²

Flexibility Provided by Utilizing On-site Generation

The easiest way to deal with DR is to shed power or turn off loads. However, this is not a popular idea among commercial and industrial energy users. Turning off machines in an industrial site can be complicated and time-consuming for on-site personnel and potentially harmful to the equipment. And more importantly, production and revenue are turned off as well. A more practical approach is to utilize on-site generation. Summary:

- Grid electricity has seen significant cost increases recently, and conventional resources can fail unexpectedly due to extreme weather conditions.

- On-site energy generation is growing in popularity for businesses of all sizes and types, including manufacturing facilities, freshwater pumping stations, nursing homes, schools, data centers, and research facilities.

- On-site power generation provides power resilience (i.e., independence from the grid), reduced energy costs, and potential revenue streams from demand response programs.

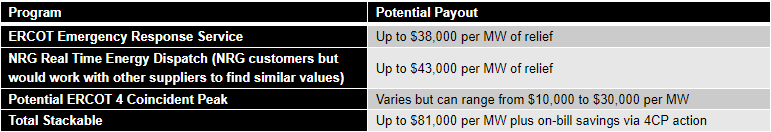

Demand Response Financial Incentives

The following table demonstrates the monies paid for active participation in Demand Response initiatives.

WPI and Generac Industrial Power

WPI has been an industrial distributor of Generac energy systems for over 30 years. We provide innovative power solutions for various commercial, industrial, and life-critical applications. With diverse generator options, high-tech mobile products, and cutting-edge transfer switches and accessories, we ensure power is always available to businesses – no matter the location, on top of a high-rise office building or a manufacturing facility.

Contact WPI today to learn how we can help you with Demand Response and implementing Practical Power Resilience™.

¹ McKinsey & Company, The Texas power crisis: Shining a light on the generation outages

² Powerstar, Applications